An odor control unit utilizing activated carbon, also known as an activated carbon odor control unit, is a device that uses the chemical properties of activated carbon to remove and neutralize odors. Activated carbon, also known as activated charcoal, is a form of carbon that has been processed to have a high surface area, making it highly porous and ideal for adsorbing a wide range of impurities and pollutants such as volatile organic compounds (VOCs), formaldehyde, and other harmful pollutants.

Activated carbon works by adsorption, a process in which molecules in a gas or liquid become trapped in the carbon’s porous structure. As the odor-causing molecules come into contact with the activated carbon, they become trapped in the carbon’s surface, effectively neutralizing the odor.

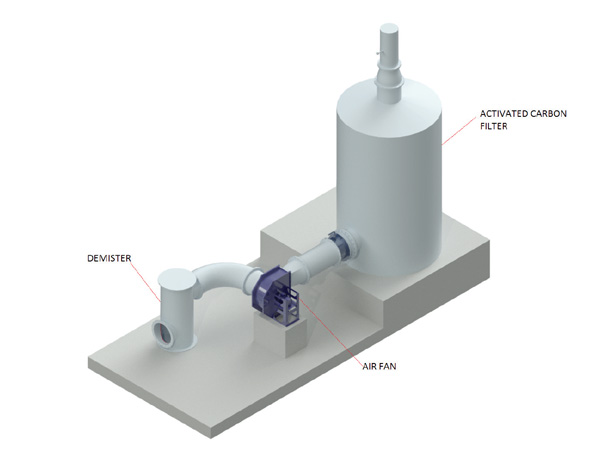

Activated carbon odor control units are commonly used in a variety of settings, including sewage treatment plants, waste management facilities, and industrial plants. They can also be used in residential and commercial buildings to remove unwanted odors such as tobacco smoke, cooking odors, and pet odors from the air. These units can be stand-alone or integrated into HVAC systems.

There are several types of activated carbon that can be used in an odor control unit, each with its own unique properties and advantages.

Powdered activated carbon (PAC) is a dry, granular form of carbon that can be easily transported and handled. It is often used in small-scale odor control applications, such as residential and commercial buildings.

Granular activated carbon (GAC) is a larger, more coarse form of carbon that is commonly used in larger-scale applications, such as sewage treatment plants and waste management facilities.

Impregnated activated carbon is carbon that has been treated with a chemical compound, such as potassium permanganate, to improve its odor-removing properties. This type of carbon is often used in industrial settings where specific odors, such as hydrogen sulfide, are present.

Activated carbon odor control units can be designed to be regenerated, meaning the carbon can be replaced, or they can be designed to be disposable, meaning the unit must be replaced when the carbon is spent.

Activated carbon odor control units are highly effective at removing and neutralizing a wide range of odors. They are also relatively low maintenance and can have a long service life. However, they can be relatively expensive to install and operate, particularly in larger-scale applications.

In conclusion, an activated carbon odor control unit is an effective solution for removing and neutralizing a wide range of odors. It uses the chemical properties of activated carbon to adsorb pollutants and odors, making it an ideal choice for industrial, commercial, and residential settings. These units can be stand-alone or integrated into HVAC systems, and come in different forms like Powdered activated carbon (PAC), Granular activated carbon (GAC) and Impregnated activated carbon